Laser feedback adjustment

Обратную связь власти и народа по-прежнему наблюдатьне удаётся, мы расскажем о более повседневном явлении:обратной связи в диодном лазере с внешним резонатором. We will briefly describe feedback alignment of ECDL (external cavity diode laser) following Toptica manual and using Axcell diodes.

Contents

Companies to purchase diodes

First you need to order diodes it takes around one month to arrive http://www.axcelphotonics.com/. It is possible to pay with a credit card, the price for one diode is 175$. Also they have Low AR coating .5%

Datasheet

General characteristics

After arrival the will have some datasheet, probably not very informative. I bought three diodes and get smth like this:

| Diode number | Kink current, (mA) | Kink power, (mW) | Current @150mW (mA) | Peak wavelength @150mW, (nm) | Central wavelength @150mW (nm) | Peak width @150mW (nm) |

| 28 | 201.57 | 159.48 | 191.7 | 777.06 | 776.97 | 0.11 |

| 34 | 201.55 | 159.76 | 191.69 | 777.22 | 777.17 | 0.41 |

| 39 | 201.58 | 158.43 | 192.64 | 777.38 | 776.7 | 0.89 |

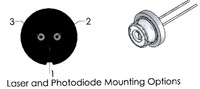

And what is even more important - the pin connection. There are two types of diodes: cathode-grounded or anode grounded. As usual diode has inside photo-diode(PD) and laser diode (LD). These specific diodes from Axcell do not have PD, see the picure below.

Determining the Laser Diode Pinout

The following assumes you know nothing about your device other than that it is a 3 to 5 mW laser diode. The first step is to identify which pair of terminals are the laser diode and photodiode. Your laser diode package will be configured like one of the following:

LD LD LD LD

+--|>|--o LDC +--|>|--o LDC +--|<|--o LDA +--|<|--o LDA

| | | |

COM o--+ COM o--+ COM o--+ COM o--+

| PD | PD | PD | PD

+--|>|--o PDC +--|<|--o PDA +--|>|--o PDC +--|<|--o PDA

(1) (2) (3) (4)

The most common polarities for low power laser diodes seems to be (2). The COM terminal will then be connected to a positive supply (+V) relative to LDC and PDA.

The photodiode (PD) will be reverse biased. Its anode (PDA) will feed a load resistor and sense amplifier for the optical feedback current regulator.

The laser diode (LD) will be forward biased. Its cathode (LDC) will connect to a driver transistor and/or network to regulate LD current based on the photodiode current and possibly a modulation circuit.

If you are leaving the photodiode installed in the optical block, also see the section: Reasons to Leave the CD Laser Diode in the Optical Block for sample connections.

Where you can see both the pins and the inside of the laser diode package, it is easy to identify which pins goes where:

The common (C or COM) will be connected to the case and the platform on which the laser diode and photodiode are mounted. There will likely be no actual pin visible inside the case.

The connection to the laser diode (LD) will attach via a fine wire to the laser diode chip which is near the front (optical window) of the package.

* The connection to the photodiode (PD) will attach via a fine wire to the photodiode chip mounted (probably at a slight angle) deep inside the package.

If you can confirm these 3 connections by inspection, only the LD and PD polarities will need to be determined experimentally.

The following assumes you did not have this luxury:

The photodiode's forward voltage drop will be in the approximately .7 V range compared to 1.7-2.5 V for the laser diode. So, for the test below if you get a forward voltage drop of under a volt, you are on the photodiode leads. If your voltage goes above 3 V, you have the polarity backwards.

CAUTION: Some laser diodes have very low reverse voltage ratings (e.g., 2 V) and will be destroyed by modest reverse voltage. Check your spec sheet. However, the laser diodes found in CD players seem to be happy with 4 or 5 volts applied in reverse. Of course, a shorted or open reading could indicate a defective laser diode or photodiode.

If the laser diode is still connected to its circuitry (probably a printed flex cable), it is likely that the laser diode will have a small capacitor directly across its terminals and the optical sensing photodiode will be connected to a resistor or potentiometer. In particular, this is true of Sony pickups and may help to identify the correct hookup.

Safety rools! Wear grounding all the time.

Diode installation

We connect it to the safety scheme (not directly to the TEC) which is installed inside of the laser. Check with multimeter polarity before connecting the diode itself. Now we will follow almost all the steps form the manual "Toptica", see pictures below.. Предполагается, что все элементы уже установлены: Скан-контроллер, Термоконтроллер, электроника лазера. Первым шагом следует аккуратно установить диод в разъем(предварительно следует проверить, чтобы схема подключения тека и диода совпадали). Далее установить бимсплиттер после диода. Поворачивая диод, можно закрепить поляризацию горизонтальной, пучок также должен иметь вид эллипса с главной осью параллельной горизонту. Далее следует сколлимировать пучок двигая линзу (обычное фокусное расстояние линзы 2-4.5 мм, трубка и линза стоят около 100$ (ThorLabs - LT230P-B 117$) ). Следует учесть, что для разных диодов нужно подбирать свое фокусное расстояние. Сколлимированный пучок должен не менять размера по крайней мере десять метров. В следующей части опишем установку дифракционной решетки (Grating) и преодоление порога лазерной генерации.

Feedback adjustment

The only difference will be in first step where we align two ellipses one under another. We need roughly find place where the frequency will be close to our. In steps. Starting with a coarse adjustment of Feedback.

- Adjust Iset to halfway between lasing threshold and Imax.

- Rotate grating holder until two visible spots ae vertically aligned one above the other. Fix grating holder with screw 6.

- Adjust grating holder with screws 4 carefully until both visible spots overlap and the spot 'flashes'.

- FIne adjustment of feedback is an iterative process. Turn down Iset so that the bright area is just visible (for me it was I = 50 mA). Readjust grating by turning the micrometer screw for wavelength adjustment and using screws 4 until the spot 'flashes' again.

- Best fine adjustment is made whrn 'flashing' is just visible with the lowest Iset possible.

- Tighten screws 4. Take care not to misalign the feedback of the laser light.

- Check whether the lasing threshold I_min_th is at least 10% below I_free_th of the free running laser diode

- Mount correction mirror

- Next step is frequency tuning.

List of cites

- Toptica manual