Laser assembly

Here we describe how to build a diode laser.

Mechanical parts assembly

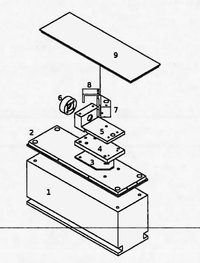

Step one in construction of the Laser was to assemble the thermal masses. The thermal masses are components 1,2,4 and 5 in Figure (*). If the temperature of the laser was to change even slightly, the length of the laser cavity would also change resulting in a change in the wavelength at which the laser was running. A temperature change could also result in a mode hop to a different range of wavelengths. For this reason it is important to have a set of thermal masses that can be used as a heat sink by the temperature controller. In order for the temperature of the laser to be controlled, a thermistor was inserted into the thermal masses. This was done by drilling a small hole in the side of part 5. The hole was as close in diameter to that of the thermistor as possible, and was just deep enough that the head of the thermistor coulf be made flush with the outside of part 5. A second hole was drill and taped just above the first one such that a screw could be inserted so that the screw head would hold the thermistor in place.

Since parts the thermal masses are going to be near the optical components of the laser it was important to clean them throughly with acetone. Parts 3 through 8 were first cleaned in a sonic bath in order to remove the small contaminants that are deeply imbedded in the masses. Once the parts were clean, thermal paste was spread between parts 4 and 5 and they were attach together. The thermal paste ensures good heat conductivity between parts. Both sides of the peltier were covered with thermal paste and placed between parts 4 and 2, and these parts were attached together. Note that part 3 in the figure(*) is out of place in order to allow for a clear view of all the parts. It was actually placed on top parts 1 through 8 once they had been properly assembled. Parts 1 and 2 wer attached together with a layer of thermal paste on the contact points. Finally the thermistor was coated with thermal paste and secured in the hole prepared for it. The thermal masses of the laser are now assembled.

To make a frame

Mistakes which are found from my experience. (A) On the figure ** we can see that installation of BIAS-TEE and FET do need to be moved to the right, so holes for FET should be moved off-center to the lef, to leave enough space for both elements. Usually BIAS-TEE mounted from the right of the FET. (B) On the picture *** it could be seen that mounted mirror (on part 8) interferes with the laser cover and this the only position where the hole beam falls onto a mirror, I can see only two way of solving this problem: shorten part 8 or place the hole holder 4-5 off center. (C) Next step is to insert a diode and align feedback. Laser feedback adjustment

Electronics preparation

Laser diode installation

Safety rools! Wear grounding all the time.

Настройка диодного лазера конфигурации littrow. Первым шагом следует аккуратно установить диод в разъем(предварительно следует проверить, чтобы схема подключения тека и диода совпадали). Install the PBS (polarizing beam splitter) after the diode.

Turning diode... Поворачивая диод, можно закрепить поляризацию горизонтальной, пучок также должен иметь вид эллипса с главной осью параллельной горизонту. Далее следует сколлимировать пучок двигая линзу (обычное фокусное расстояние линзы 2-4.5 мм, трубка и линза стоят около 100$ (ThorLabs - LT230P-B 117$) ). Следует учесть, что для разных диодов нужно подбирать свое фокусное расстояние. Сколлимированный пучок должен не менять размера по крайней мере десять метров. В следующей части опишем установку дифракционной решетки (Grating) и преодоление порога лазерной генерации.