Vacuum Components

Contents

Pressure ranges

| Vacuum quality | Torr |

|---|---|

| Atmospheric pressure | 760 |

| Low vacuum | 760 to 25 |

| Medium vacuum | 25 to 10^-3 |

| High vacuum | 10^-3 to 10^-9 |

| Ultra high vacuum | 10^-9 to 10^-12 |

| Extremely high vacuum | < 10^-12 |

| Outer space | < 10^-6 to <10^-17 |

| Perfect vacuum | 0 |

Mean free path:  , where

, where  is a scattering cross-section, n- concentration of molecules. For a nitrogen the table with mean free paths versus pressure is given here. For our pressure

is a scattering cross-section, n- concentration of molecules. For a nitrogen the table with mean free paths versus pressure is given here. For our pressure  is 5.9 10^3 m.

is 5.9 10^3 m.

Getters vs dispensers

In order to improve and maintain the vacuum environment inside hermetically sealed devices, the getters materials play a pivotal role: the getter material can sorb all active gasses such as O2, H2O, CO, CO2 and N2 by a chemical reaction under vacuum.

AMDs keep the alkali metal pure in the form of a stable salt combine with a getter material. The presence of the getter guarantees an ultrapure environment during the alkaly evaporation. Yield is measured in mg/cm.

Companies

Contacts: (719)5763200, SAES getters U.S.A. Inc. 1122 I Cheyenne Mountain Blvd Colorado Springs, CO 80906 ([1])

| length, [mm] | 12 | 17 | 25 | 40 | 50 | 60 | 350 | 1000 |

| weight, [mg] | 3.4 | 4.8 | 7 | 11.2 | 14 | 16.8 | 98 | 280 |

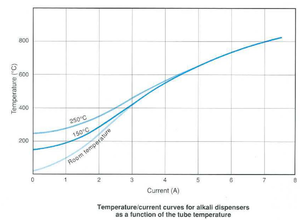

All the alkali metals evaporate between 550 and 850 C

Gases released from dispensers: about 1 cc torr/cm where hydrogen was the prevailing constituent. The practical range of current for most dispensers is from 4.5 to 7.5 A. Original packing guarantees a one year shelf life. Dispensers can be exposed to the atmosphere for short periods of times without problems. However, after the original packing has been opened, they must be stored in either dessicators or containers under vacuum.

From email: The following are the product codes for the Rubidium Dispensers that are available. The costs are about $46.58 per dispenser. A standard package is 50 pieces per can. Orders requiring quantities other than multiples of standard packaging (increments of 10 each only) will be subject to a canning charge of 30.00 per can. The minimum order value requirement is $650.00. The shield life is 2 years for the date of manufacturing.

Please let us know which part number you would like to quote and the quantity of sets of 10.

-RB/NF/3.4/12 FT10+10

-RB/NF/4.8/17 FT10+10

-RB/NF/7/25 FT10+10

-RB/NF/11.2/40 FT10+10

-RB/NF/14/50 FT10+10

-RB/NF/16.8/60 FT10+10

-RB/NF/98/350 FT10+10

-RB/NF/280/1000 FT10+10

Our experience

Dispensers welding does Colin in the workshop

We usually connect 3 dispensers in series, we work at 3 A, when the dispensers are fresh.

Companies

huntvac.com

Gaskets + flanges

Materials to use in UHV

Starting vacuum

Bake out is one of the stages. Bake-out should be continued until 100 times the expected ultimate pressure is attained. The heaters for the pump and vacuum chamber are then switched off. After cool-down, the desired ultimate pressure will probably be achieved.