Electronic parts of ECDL

For ECDL we need different types of control, installed as inside of laser as connected externally through BNCs and 15pin Dsub. Mainly consists of the next components:

- FET

- Scan controller

- TEC

- BIAS-TEE

Contents

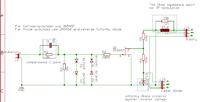

Stromklau FET

From the very beginning. This schematic is build to send TTL signal to a laser directly through current modulation. For example, for optical phase-locked loop. Since the instantaneous bandwidth of a typical ECDL may span as much as a few hundreds of kilohertz, the loop must be made as fast as possible in order to correct for this noise. The loop must as well be able to correct for the low-frequency noise and drifts due to mechanical vibrations. To achieve the required frequency range, dual feedback was employed: by modulating the external cavity length with a piezo-electric transducer and by direct modulation of the injection current. The bandwidth of the piezo modulation is limited to a few kHz by mechanical resonances, but it allows significant correction to the laser frequency. On the other hand, the current injection modulation is fast (up to a few MHz), but the frequency corrections are limited by modehops.Safety-circuit-board inside the laser. J1- to TEC using pins 3,10,11 on a 15 pin Jack, J2- to BNC(TTL) for examle used in a phase-lock, J3 connected directly to the diode. Electronics/eagle/Fet-DL100

Indeed the diodes just limit the Gate-Source voltage to two diode forward- voltage-drops (approx +-1.3 V). We use 1N4148 diodes, as they are common and don't add much capacitance.

The purpose of the capacitor C13 || R38 is to approximately compensate the low-pass behavior caused by the gate capacitance and the protection diodes' capacitance. We find that in our boards a much lower value than used in the Toptica gives a reasonably flat gain profile up to >20 MHz.

Concerning the J-FET: For a cathode-grounded laser diode, use a 2N5457 JFET, for anode-grounded laser diodes, use a 2N5460. Please note that on the picture an arrow (marking differently NPN or PNP transistors) is facing the wrong side.

For your convenience, please find attached a layout for a strip-prototype-PCB as we use it currently for our lasers.

For high-current lasers, you might have to reduce the value of the 5R6- resistors, if your current driver cannot supply a high enough voltage.

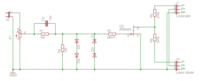

Scan-controller

It is so-called controller of the laser. I won't describe electronic part in a detail, it mainly consists of a few logical parts: (a) ramp signal generator (b) ramp signal modification - amplitude and offset (c) signal amplifiation (d) fine current adjust (e) feedfoward (f) swithces for temperature and current control. See schematic and front panel in a picture below.

TEC and current control

The purpose of a TEC is to stabilize the temperature of the laser to a predetermined temperature, as quicly as possible. And to send a certain current through the diode. We use commercially available ITC102 from thorlabs. It costs 600$, plus for the panel additional ~220$. It is useful to read manual for the TEC. We connect it to a peltier element and to a temperature sensor AD590KH-ND . Pin connection see on a picture below:

BIAS-TEE

In addition to FET we install Bias-tee inside of the ECDL, which can be found in mini-circuit's shop with a partial number ZFBT-4R2G-FT+. Frequency range from 10 to 4200 MHz. For example: it could be used to stabilize the length of the OPO cavity a Pound-Drever-Hall locking system was constructed: a diode laser’s injection current is modulated with a 30 − 60 mV rms , 20 MHz signal, which is added to its DC component via a Minicircuits ZFBT-4R2GW-FT bias-tee.

Optical phase-lock loop

OPLL is used to lock your ECDL phase to another laser. Current version affords frequency differences between master and slave lasers up to 7 GHz.